The usual FET testing technique is to pre-charge the gate, not touch it again and then measure the source-drain resistance, which must be low with a charged gate. That doesn't work with IGBTs. Neither does the classic bipolar testing method work.

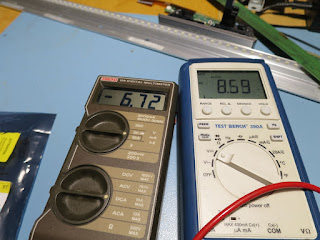

To properly test IGBTs, we need a test fixture. This circuit simply applies a variable voltage to the gate and the emitter-collector current goes through a resistor. We measure the gate voltage and the E-C current.

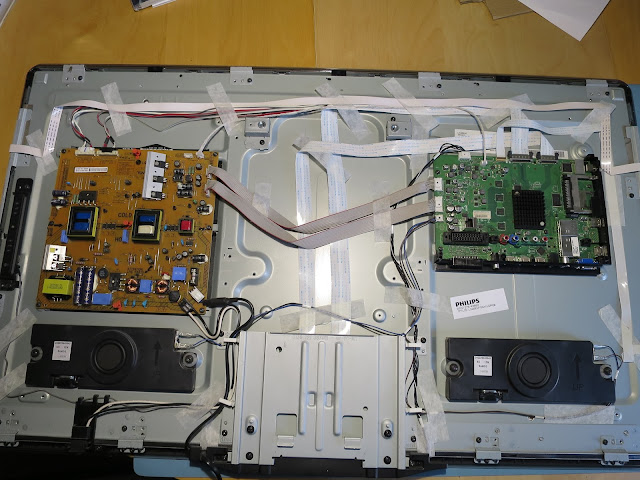

To test the SMD IGBTs I quickly solder the gate and the emitter to the board. The collector is connected to the tab and a gentle push on top of the device connects it to the large pad.

The 30F131 starts opening at slightly under 4V GE (gate-emitter) voltage. It is open at 5V.

The DG302 starts opening just above 5V, it is open at about 5.8V.

The RJP30H2A starts opening at about 4.2V and is open at 5V.

I spent a considerable time studying the offers on Aliexpress. Some were easily detectable as fakes. When the character font used for labeling is obviously wrong, the numbers are not engraved into the casing or the stamp in the center is missing or different, it must be fake. The pictures of the seller I ordered from seemed ok. Either they were more careful faking it or I get lucky :-)

I have a pending delivery of the 30F131 and RJP from China. I am going to check against fake devices with this test technique. The tests above have been conducted with original parts. I always keep some originals as a reference.

Update: Fake IGBTs

The RJP from China are obviously fake. Neither do the look the same, nor do they measure like the original. I will not bother using them to avoid further damage to the board.Don't buy them from "Chinese Super Electronic market". I recon, to get originals you will have to spend a few dollars per piece.

The F131 don't look the same, but they behaved ok in the measurements. I am still not confident to use them.

I also ordered the driver transistors (SMD 3Y) and the control chip from that seller. I'll test those later.

I've put the fake transistors under the microscope. Please see this blog post.

C-E Reverse Break-Through Voltage Test

Another very revealing test is to measure the reverse break-through voltage between emitter and collector. I use my DUOYI DY294 tester for this.- The orginial RJP has 230V. The chinese fake only 45V(!!). I'll dump that garbage right into the trash.

- The original F131 has 110V, so does the chinese. Maybe those are not so fake.

- The original RF1501 diode has 375V, the chinese is right on the spot. Forward voltage is identical, too. So, those are most likely legit. They also look absolutely identical.

RF1501 diode is ok

In the meantime I fixed another 50GT30 with one of the RF diodes and they are working flawlessly. I can recommend the source for those.

https://www.aliexpress.com/item/10PCS-RF1501-RF1501NS3S-TO-263/32515394351.html

https://www.aliexpress.com/item/10PCS-RF1501-RF1501NS3S-TO-263/32515394351.html